Making Automation Simple

Red-Eye Leak Detection System

RED-EYE is a patented oil leak detection system, utilizing photoelectric laser sensor technology to detect stuffing box leaks. If a leak is detected, a notification is sent to the user, who may then respond accordingly. RED-EYE helps your business remain compliant with regulations, without the mess of liquid or gas containment.

RED-EYE’s on-board photo-eye uses a laser to scan the top of the stuffing box, recognizes the presence of oil along the top of the stuffing box, then takes a picture and sends a text alert to the user so they can act. RED-EYE is,

- Simple to mount on the pumping unit, no need to remove equipment for well work.

- A class-1 laser photo-eye is safely used so it is not hazardous to eyes or skin.

- Sees everything during day or night with wide-angle views, working up to 20 feet away.

- Take action in seconds with on-board IloT, transmitting events to the cloud then the user.

- Shuts down the well automatically or other customizable actions.

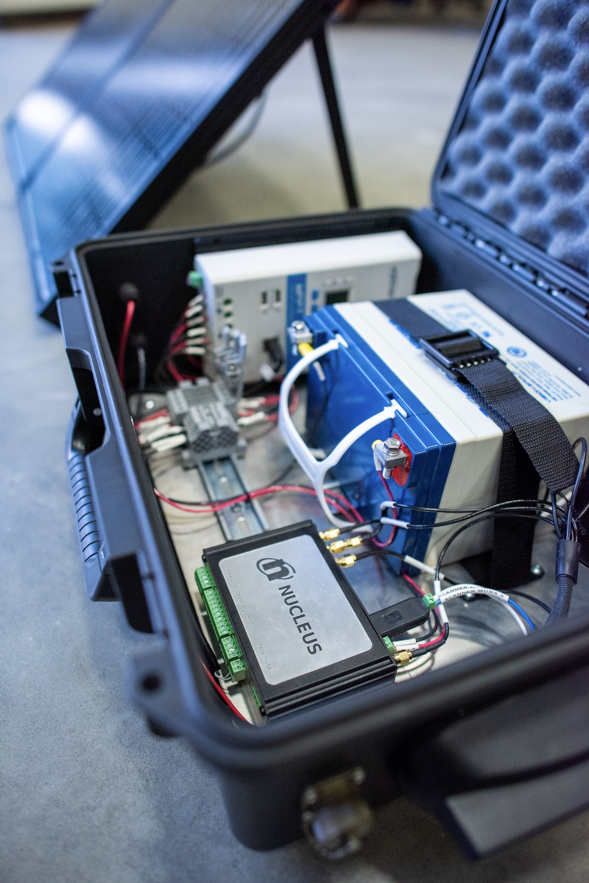

Off-Grid Package

Portable monitoring and controls fold and solar panels. Takes 3 minutes to set-up & tear-down.

- Ideal for monitoring points of interest in remote locations

- Connect sensors, gauges, meters, & more with the on-board NUCLEUS

- Data is stored securely in the Tyrion Cloud

- Access real-time data on your mobile device or PC

- Visualize trends & make informed decisions about your processes

Automated Injection Monitoring

Automated Injection Monitoring (AIM) is a flexible turn-key solution built on our OFF-GRID PACKAGE. AIM continuously monitors underground injection pressures and streams real-time data directly into the cloud.

AIM can record well-specific injection pressures, including the highest instantaneous injection pressures each month.

AIM reports necessary data to provide to CalGEM and automatically alerts operators to ensure max pressure is not exceeded.

AIM retains injection pressure records, maintained by operators, as long as the well is approved and for three years after.

Easily install and integrate with new or existing infrastructure, deploy a mobile unit as needed on your own, or let us manage the install and deployment at your convenience.

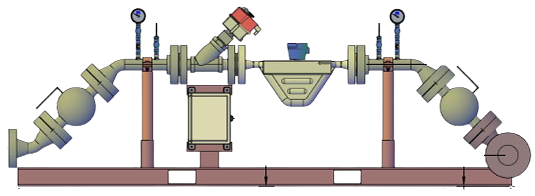

Gas Lift

TYRION’S AUTOMATED GAS LIFT SYSTEM increases efficiency and safety by optimizing gas injection into the well and reducing the need for manual intervention, which LEADS TO INCREASED OIL PRODUCTION RATES.

- Revive production in declining wells

- Real-time monitoring and controls

- Ready for quick installation

Gas lift operations are conveniently monitored by NUCLEUS in Tyrion’s cloud-based platform, making it simple to manage controls & monitor trends.

Need more information? Contact us to speak with one of our experts.